Exploring Thermoplastic Foam Injection Molding: Benefits and Applications in Modern Manufacturing

Release time:

2025-08-18 10:22

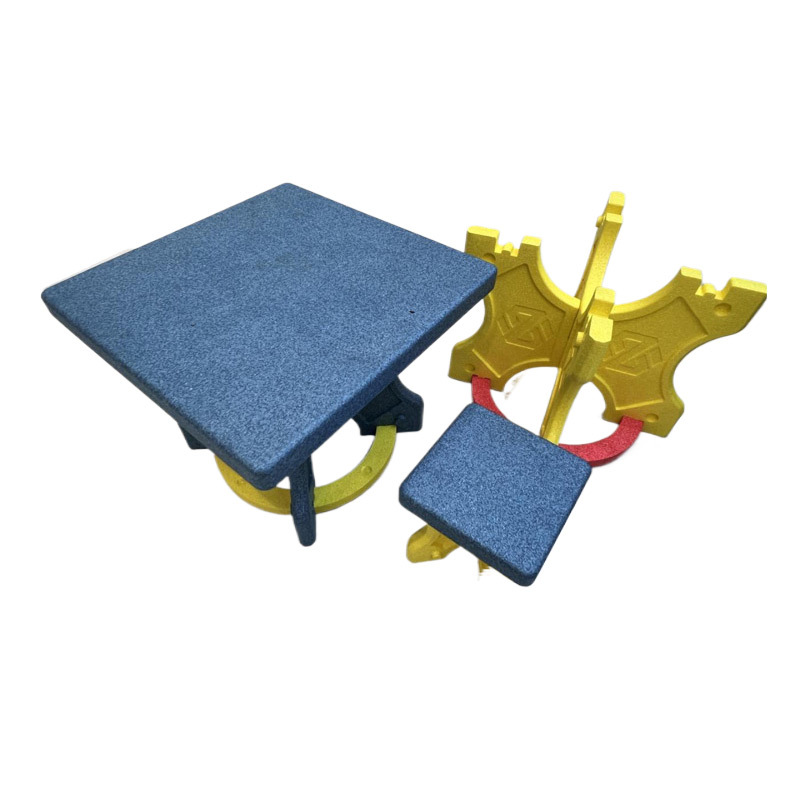

Thermoplastic foam injection molding is a process that allows manufacturers to create lightweight, yet strong components by injecting a thermoplastic material that expands into a foam state. This technique is particularly useful in sectors where weight savings are critical without compromising structural integrity. The process begins with melting the thermoplastic resin, which is then mixed with a blowing agent that facilitates the expansion into foam. This results in an end product that is not only lighter than conventional solid thermoplastics but also offers excellent insulation properties.

One of the primary benefits of thermoplastic foam injection molding is its efficiency in material usage. By filling the mold with foam rather than solid material, manufacturers can reduce the overall weight of their products while minimizing waste. Additionally, the foam structure often provides better thermal and acoustic insulation, making it ideal for applications in automotive parts, consumer electronics, and construction materials.

Moreover, the process enables the production of complex geometries that are difficult to achieve with traditional solid molding methods. The flexibility of thermoplastic foam allows for intricate designs that maintain strength and durability. This becomes especially relevant in industries that require customized solutions or components tailored to specific applications.

Another significant advantage is the recyclability of thermoplastic materials. Once a product has reached the end of its life cycle, the thermoplastic foam can be reprocessed and reused, promoting sustainability within manufacturing practices. This environmental consideration is increasingly important as industries seek to reduce their carbon footprint and embrace greener technologies.

Thermoplastic foam injection molding also offers faster production cycles, which can enhance productivity in manufacturing operations. The rapid cooling and solidification of thermoplastics result in shorter cycle times, allowing companies to meet market demands more efficiently. This aspect can be particularly beneficial in a competitive landscape where time-to-market is crucial.

In conclusion, thermoplastic foam injection molding represents a significant advancement in manufacturing technology, particularly within the mold-making and stamping industries. By leveraging the lightweight and insulating properties of foam combined with the versatility of thermoplastics, manufacturers can produce high-quality components that meet the evolving needs of various sectors. As industry standards continue to emphasize efficiency and sustainability, this innovative process is poised to play a vital role in the future of manufacturing.

thermoplastic foam injection molding

Previous Page

Related News