Epu Foaming Molds

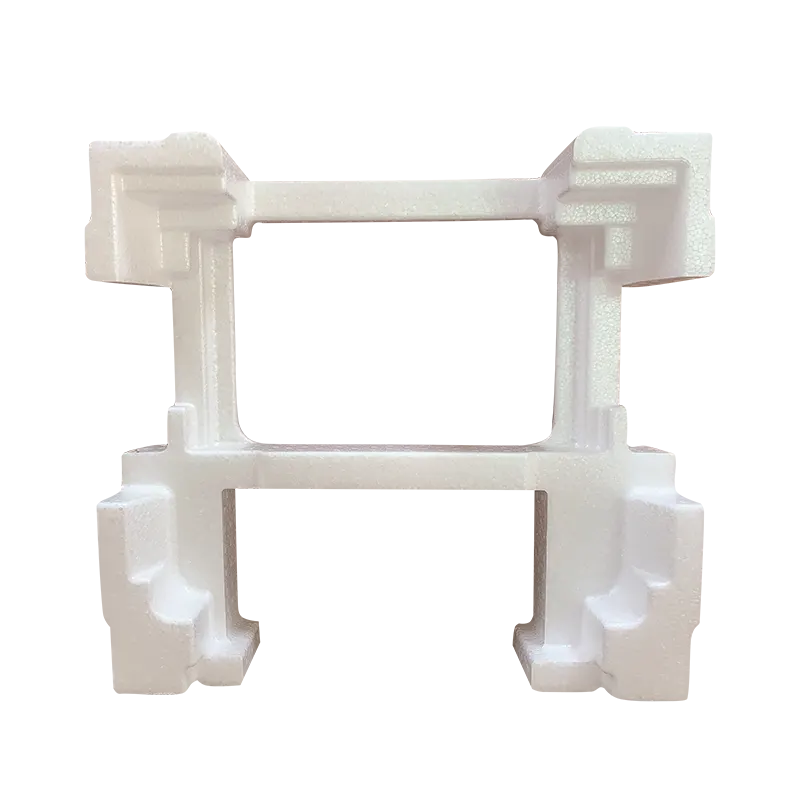

EPS (expanded polystyrene) molds are specialized tools used for manufacturing EPS products. These molds are crucial for shaping EPS into various forms and sizes, fulfilling diverse application needs. EPS is widely known and used as a cushioning packaging material for home appliances such as televisions, refrigerators, washing machines, and instruments.

Classification:

EPS foam products

Key words:

Sincashin

Product Details

EPS (expanded polystyrene) molds are specialized tools used in the manufacture of EPS products. These molds are critical for shaping EPS into various shapes and sizes to meet diverse application needs. EPS is widely used and familiar as a cushioning packaging material for home appliances such as televisions, refrigerators, washing machines, and instruments.

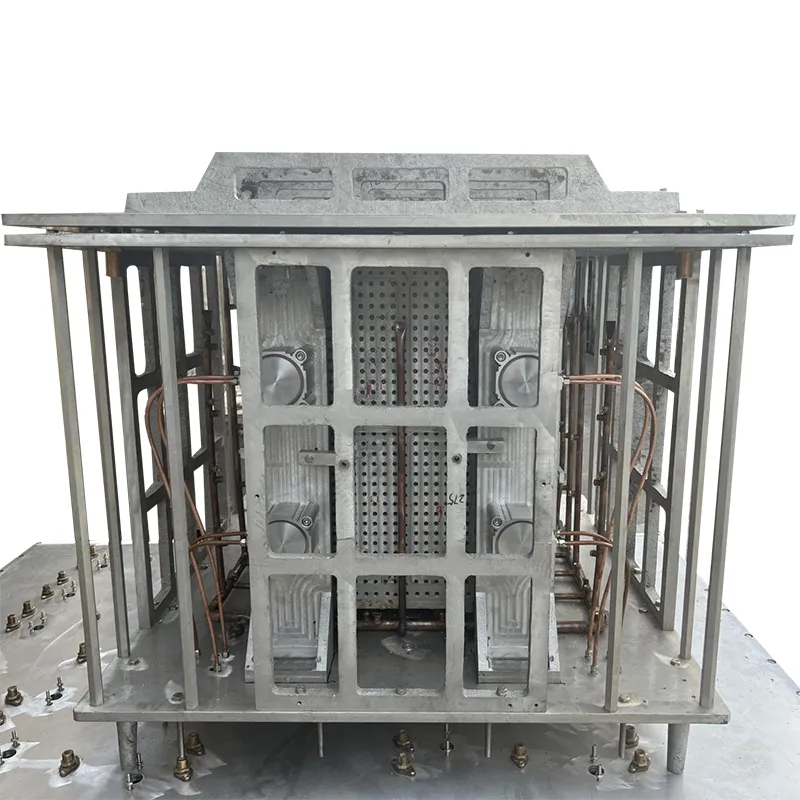

EPU foaming molds are a versatile and essential tool in various manufacturing processes. These molds are designed for producing high-quality foam products with excellent precision and consistency. The term "EPU" stands for Elastomeric Polyurethane, which is a type of durable material used to create robust and flexible molds. These molds are commonly used in industries such as automotive, furniture, and packaging, where foam products are essential.

One of the main advantages of EPU foaming molds is their ability to withstand high temperatures and pressure. This durability ensures that the molds maintain their shape and performance even during prolonged use, making them an ideal choice for mass production. Whether for creating cushions, car seat foam, or packaging materials, EPU foaming molds are designed to offer exceptional results every time.

The versatility of these molds is another key feature. They can be used to produce a wide range of foam types, including rigid and flexible foams, as well as varying densities. This flexibility makes them suitable for different applications, whether it’s for soft, comfort-driven products or stronger, more rigid foam used in structural applications. The precision with which these molds operate allows manufacturers to produce foam components that meet strict dimensional and quality requirements.

Additionally, the ease of use of EPU foaming molds contributes significantly to their popularity in industrial settings. These molds are designed to be easy to handle and maintain, which reduces downtime and increases production efficiency. The molds also promote faster curing times, which helps in speeding up the overall manufacturing process. This efficiency is crucial in meeting tight production schedules while ensuring product quality.

Previous Page

Next Page

Related Products

online message

Please leave your email and we will contact you as soon as possible, thank you!