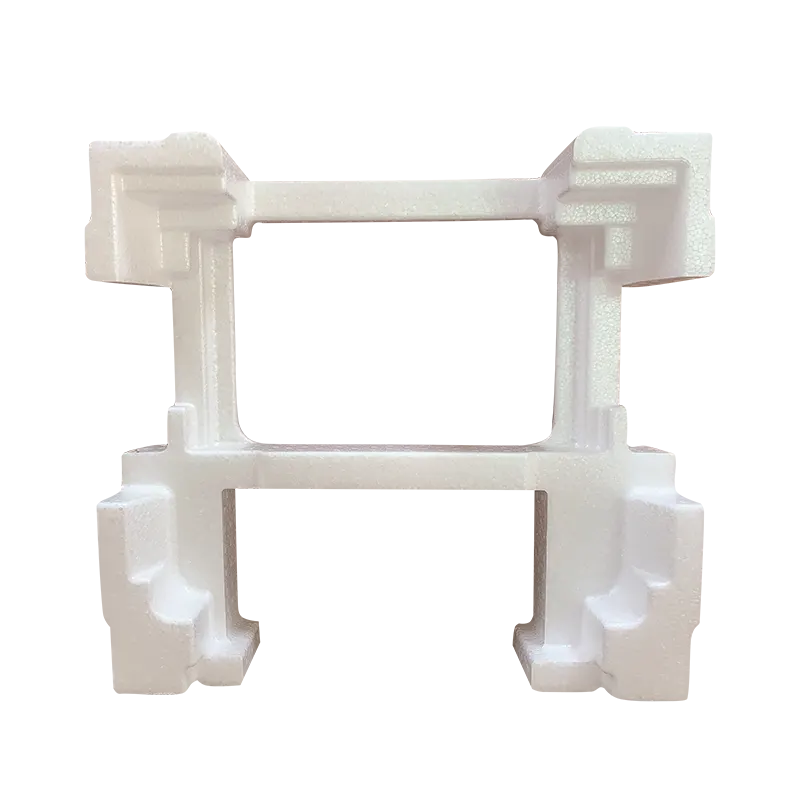

Foamed products

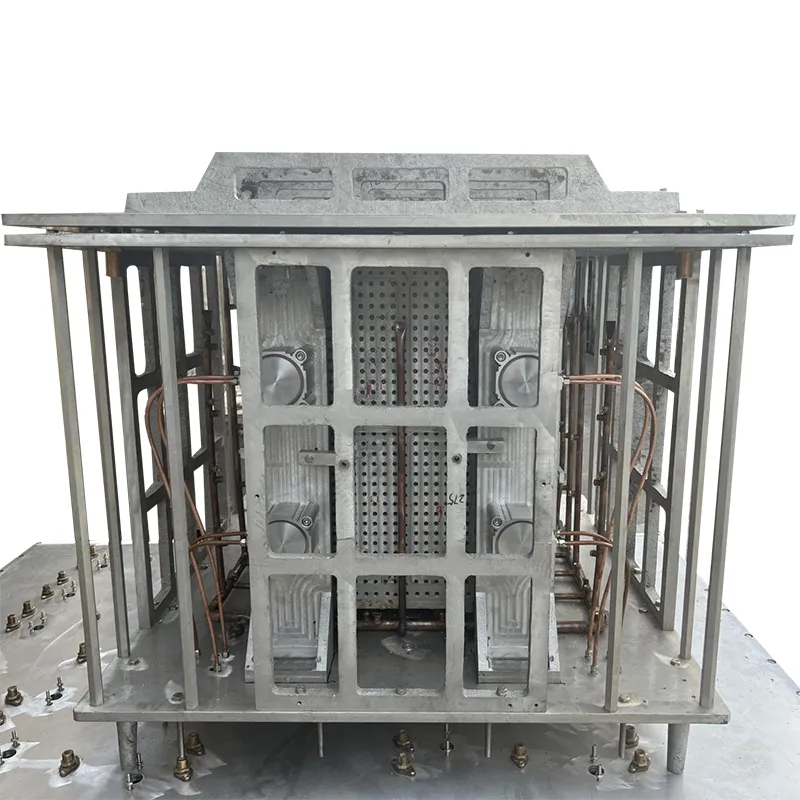

EPS (expanded polystyrene) molds are specialized tools used for manufacturing EPS products. These molds are crucial for shaping EPS into various shapes and sizes, meeting diverse application needs. EPS is widely used and familiar as a cushioning packaging material for home appliances such as televisions, refrigerators, washing machines, and instruments.

Classification:

EPS foam products

Key words:

Sincashin

Product Details

EPS (expanded polystyrene) molds are specialized tools used for manufacturing EPS products. These molds are crucial for shaping EPS into various shapes and sizes, meeting diverse application needs. EPS is widely used and familiar as a cushioning packaging material for home appliances such as televisions, refrigerators, washing machines, and instruments.

The Foamed Product Mold is an innovative solution designed for efficient and high-quality production of foamed materials. This mold is engineered to meet the demands of modern manufacturing, providing precision, durability, and versatility. With the Foamed Product Mold, manufacturers can produce a wide range of foamed products including packaging materials, cushions, insulation components, and various industrial applications.

This mold is constructed using high-quality materials that ensure long-lasting performance and resistance to wear and tear. The Foamed Product Mold is carefully designed to maintain uniformity in shape and size, which is crucial for maintaining product consistency. Its precise engineering reduces waste during production and improves overall efficiency. The mold can accommodate different types of foaming agents and materials, making it suitable for multiple industries such as automotive, furniture, construction, and consumer goods.

One of the main advantages of the Foamed Product Mold is its ease of use. The mold is designed for quick assembly and disassembly, which simplifies the cleaning and maintenance process. This feature allows manufacturers to switch between different product designs without significant downtime. In addition, the mold is compatible with both manual and automated production systems, offering flexibility depending on the scale and nature of the production line.

The design of the Foamed Product Mold also emphasizes safety. All components are manufactured to meet industry safety standards, minimizing the risk of accidents during operation. Its ergonomic design ensures that operators can handle the mold efficiently while maintaining comfort and reducing fatigue.

The Foamed Product Mold is available in various sizes and configurations to match the specific requirements of different projects. Whether producing small-scale prototypes or large-scale industrial components, this mold can deliver high-quality results consistently. Manufacturers can also customize the mold design to fit unique product specifications, ensuring that every foamed product meets the desired quality standards.

Previous Page

Next Page

Related Products

online message

Please leave your email and we will contact you as soon as possible, thank you!