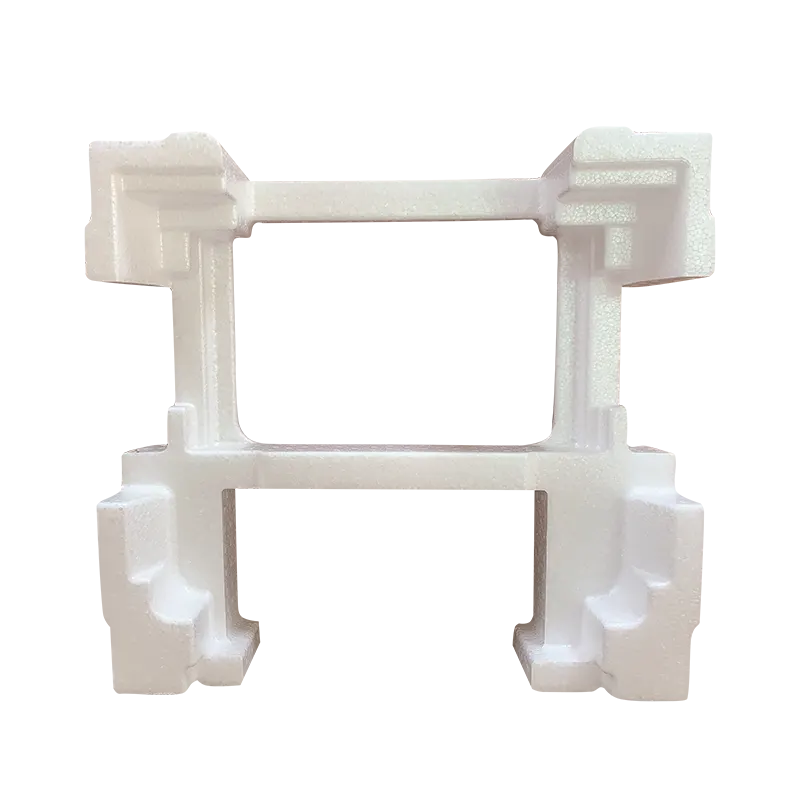

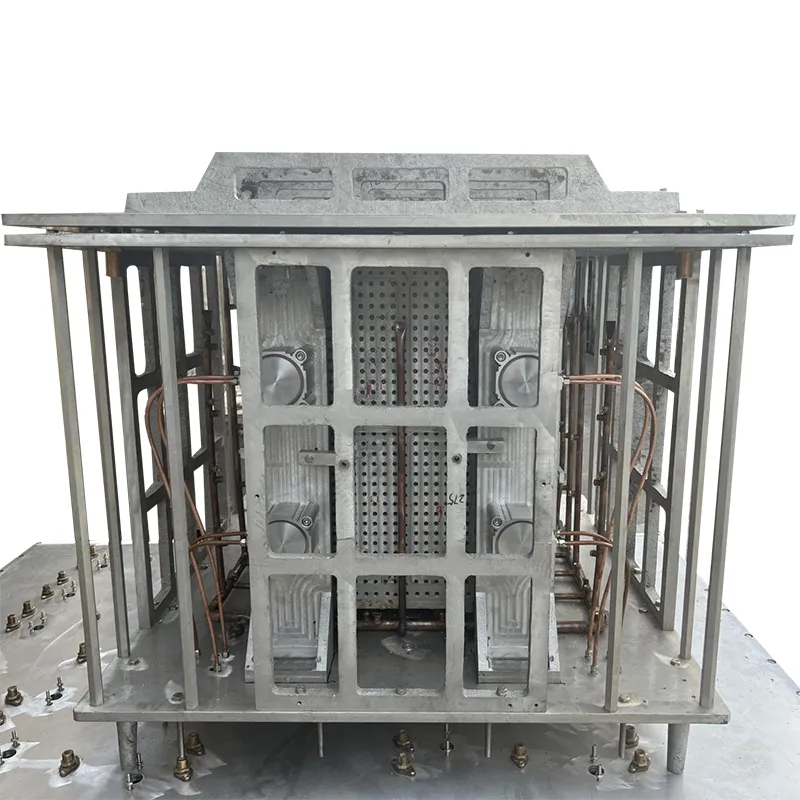

Foaming mold

Foaming mold in English: foaming mould. Foaming resin is directly filled into the mold, heated and melted to form a gas-liquid saturated solution. Through nucleation, a large number of tiny bubbles are formed, and the bubbles grow to produce foam plastic parts. There are three common foaming methods: physical foaming, chemical foaming, and mechanical foaming.

Classification:

Foaming mold

Key words:

Sincashin

Product Details

Foaming mold: foaming mould. Foaming resin is directly filled into the mold, heated and melted to form a gas-liquid saturated solution. Through nucleation, a large number of tiny bubbles are formed, the bubbles grow, and a foam plastic part is produced. There are three commonly used foaming methods: physical foaming, chemical foaming, and mechanical foaming.

Precautions

1: After prolonged use, the mold must be sharpened. After grinding, the cutting edge must be demagnetized and cannot be magnetic, otherwise it is easy to cause blockage.

2: Springs and other elastic parts are the most easily damaged during use, usually showing breakage and deformation. The solution is to replace them. During replacement, pay attention to the specification and model of the spring. The specification and model of the spring are confirmed by three items: color, outer diameter, and length. Only when the three items are the same can the replacement be made.

3: During the use of the mold, the punch is prone to breakage, bending, and damage, while the punch bushing is usually damaged. Damaged punches and punch bushings are usually replaced with parts of the same specification. The parameters of the punch mainly include the working part size, the installation part size, and the length size.

4: Fastening parts. Check if fastening parts are loose or damaged. Replace them with parts of the same specification.

5: Pressure parts such as pressure plates and urethane rubber, and unloading parts such as stripping plates and pneumatic ejectors. During maintenance, check the accessory relationships and any damage in each part, repair the damaged parts, check pneumatic ejectors for leaks, and take measures according to the specific situation. For example, replace damaged air pipes.

Previous Page

Related Products

online message

Please leave your email and we will contact you as soon as possible, thank you!