Aircraft Model Mold

At present, we provide customers with (EPS, EPP, EPO, EPU) foaming molds, pulp molds, leather molds, heating plates, helmet molds, die casting and stamping molds.

Classification:

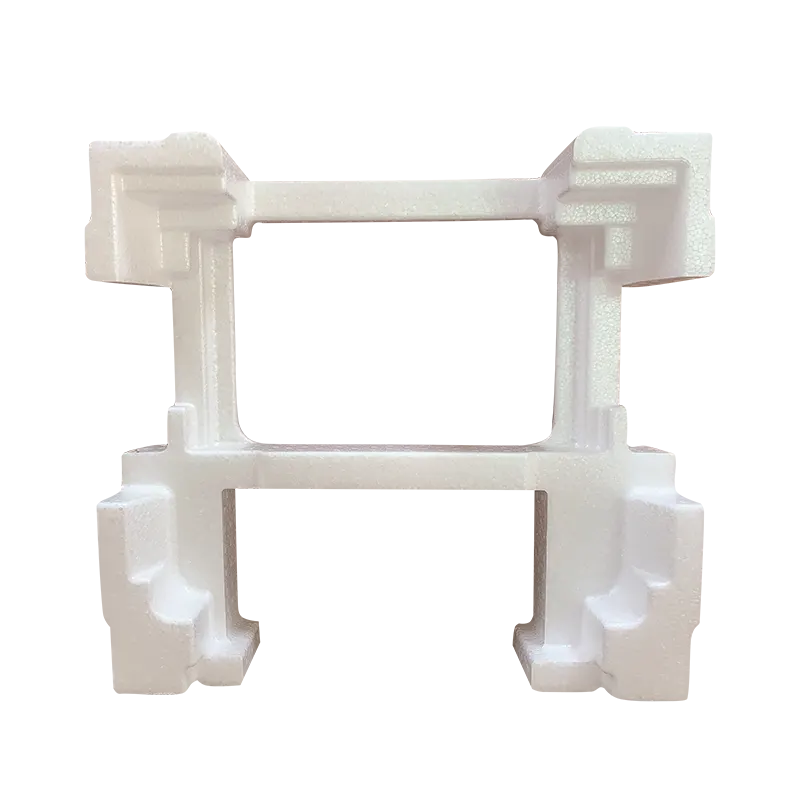

EPP foam products

Key words:

Sincashin

Product Details

At present, we provide customers with (EPS, EPP, EPO, EPU) foaming molds, pulp molds, leather molds, heating plates, helmet molds, die casting and stamping molds.

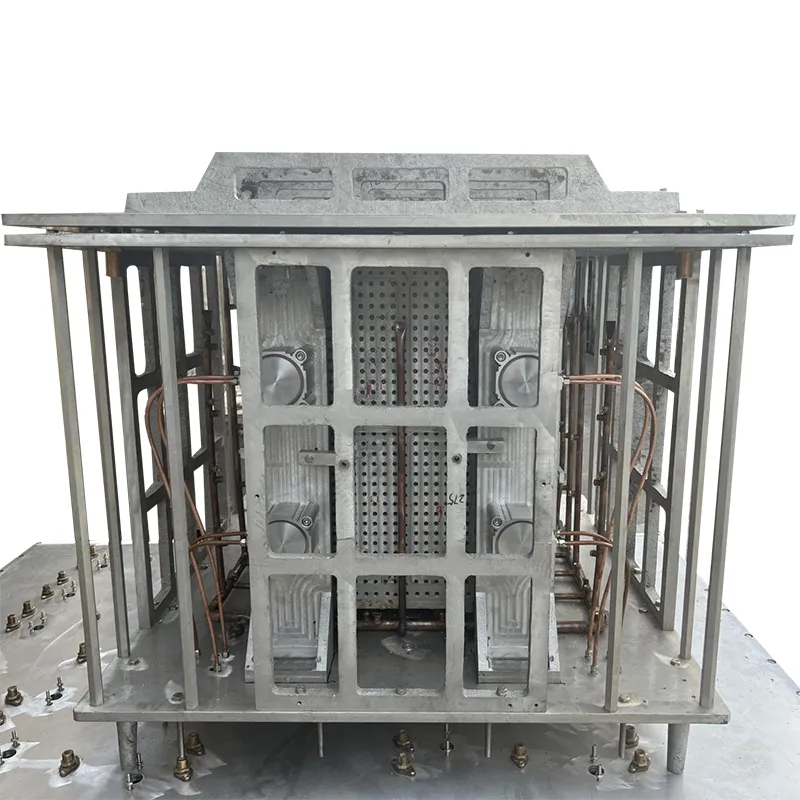

Aircraft Model Molds are specialized tools engineered to produce highly accurate replicas of aircraft, serving industries such as aerospace engineering, education, and collectibles. These molds are designed with meticulous attention to detail, ensuring that every curve, panel, and component of the original aircraft is faithfully reproduced in the model, whether for functional testing or display purposes.

Crafted from aerospace-grade aluminum, Aircraft Model Mold offers exceptional durability and precision. Aluminum’s ability to maintain tight tolerances—often within fractions of a millimeter—makes it ideal for capturing the intricate features of aircraft, such as winglets, engine nacelles, and landing gear. This material also withstands the repeated heating and cooling cycles of injection molding or casting processes, ensuring consistent quality across hundreds or even thousands of model productions.

A key capability of Aircraft Model Molds is their handling of miniaturized components. Modern aircraft, both commercial and military, include complex systems like avionics bays and fuel lines, which must be scaled down accurately in models. The molds are engineered to replicate these tiny structures without compromising their form or functionality, allowing engineers to test aerodynamic properties or assembly processes on a smaller scale before full-scale production.

Previous Page

Next Page

Related Products

online message

Please leave your email and we will contact you as soon as possible, thank you!