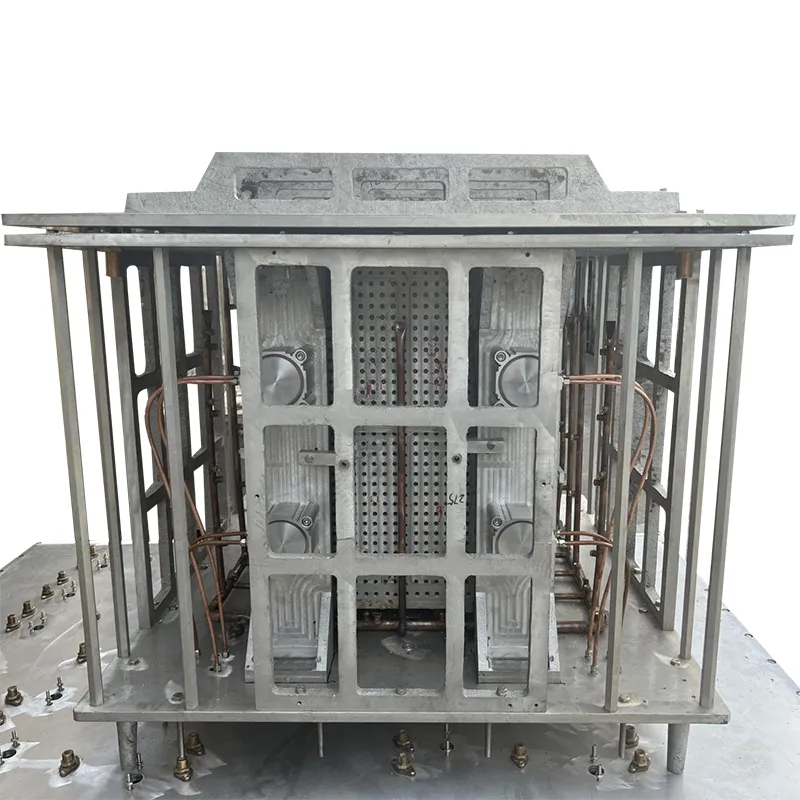

Car Bumper Mold

At present, we provide customers with (EPS, EPP, EPO, EPU) foaming molds, pulp molds, leather molds, heating plates, helmet molds, die casting and stamping molds.

Classification:

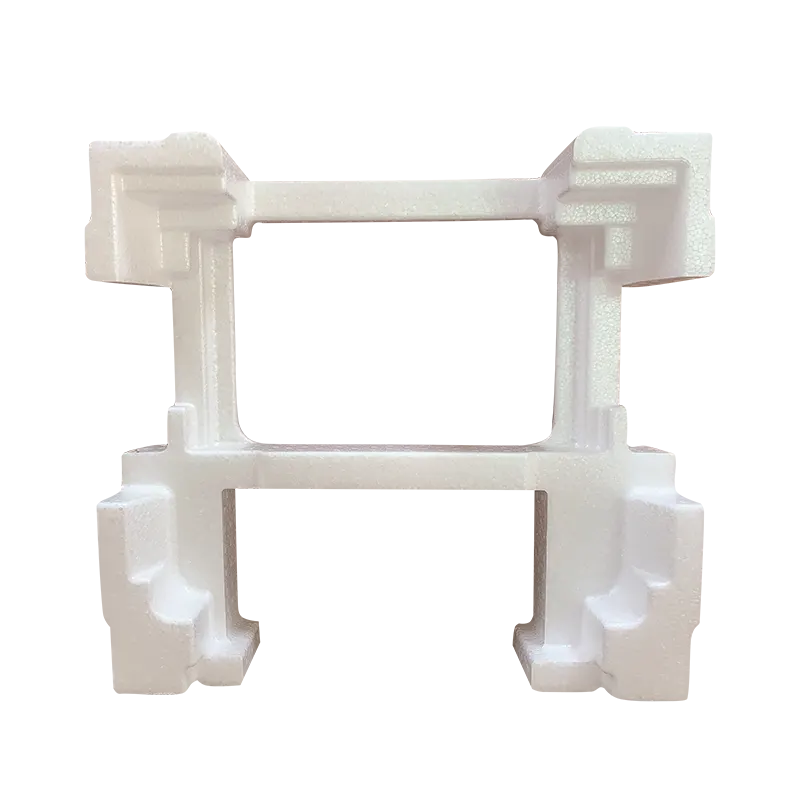

EPP foam products

Key words:

Sincashin

Product Details

At present, we provide customers with (EPS, EPP, EPO, EPU) foaming molds, pulp molds, leather molds, heating plates, helmet molds, die casting and stamping molds.

Car Bumper Molds are essential tools in automotive manufacturing, designed to produce durable and precisely shaped bumpers that balance safety, aesthetics, and functionality. These molds play a critical role in ensuring that bumpers fit seamlessly with a vehicle’s design while meeting strict industry standards for protection and performance.

Constructed primarily from high-strength steel, Car Bumper Molds offer exceptional resilience to withstand the rigorous demands of large-scale production. The steel’s robust nature ensures that the mold retains its shape even after thousands of injection molding cycles, maintaining consistent dimensions across every bumper produced. This durability is key, as automotive manufacturers require uniformity to ensure each bumper aligns perfectly with other vehicle components during assembly.

A core focus of Car Bumper Molds is optimizing impact absorption. Bumpers are the first line of defense in low-speed collisions, so the molds are engineered to shape materials—such as polypropylene or polyurethane—into structures with strategic ribs and hollow sections. These designs enhance energy dispersion, reducing damage to the vehicle and protecting occupants. The molds’ precision ensures that these impact-absorbing features are replicated exactly, guaranteeing reliable performance in real-world scenarios.

Bumpers are exposed to harsh environmental conditions, including extreme temperatures, UV radiation, and moisture. Car Bumper Molds are designed to create bumpers with smooth, uniform surfaces that resist cracking, fading, and corrosion. This is achieved through careful control of material flow and cooling within the mold, ensuring the final product maintains its integrity over time.

Previous Page

Next Page

Related Products

online message

Please leave your email and we will contact you as soon as possible, thank you!